In digital textile printing, asking the right questions can be the difference between a successful first-run project and a dumpster full of attempts. Navigating types of fabrics and constructions for different applications can get complex, but it is necessary for ultimately securing the optimal fabric from a supplier.

In digital textile printing, asking the right questions can be the difference between a successful first-run project and a dumpster full of attempts. Navigating types of fabrics and constructions for different applications can get complex, but it is necessary for ultimately securing the optimal fabric from a supplier.

When evaluating fabrics, an important factor is knowing the difference between the two methods for producing cloth: knitting and weaving.

Knitting

Knitting uses one set of yarn to form loops that interlock. Rows of loops are caught into the previous row to construct a somewhat elastic fabric, compared to the tightly twisted yarns used in weaving. There are two types of knitting: circular and warp.

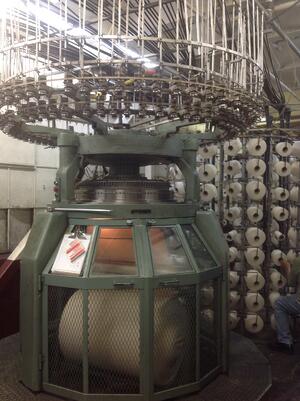

Circular Knitting

Circular knit fabrics are produced by using a knitting machine in the form of a circle. The fabric is made in the shape of a tube and will eventually be cut to lay flat before being rolled or tubed on a cardboard core for storing and printing.

Circular knits are most prevalently used in the apparel market for top weight garments and leggings — e.g., someone’s favorite casual T-shirt. The most popular types of these knit constructions are jerseys, rib knits, interlock and pique. Circular knits are most commonly printed with dye sublimation or direct digital pigment printers, if the fabric is properly optimized for the ink set.

Circular knits are most prevalently used in the apparel market for top weight garments and leggings — e.g., someone’s favorite casual T-shirt. The most popular types of these knit constructions are jerseys, rib knits, interlock and pique. Circular knits are most commonly printed with dye sublimation or direct digital pigment printers, if the fabric is properly optimized for the ink set.

Warp Knitting

Warp knitting requires a chain loom in which yarns typically run lengthwise. The yarns are set up as warps on beams, and one or more yarns run through individual needles. Warp knits create a tighter knit construction than most circular knit fabrics and often have up to four times as many stitches per inch.

These knits are used in both the apparel and soft signage markets. For apparel, warp knits are most commonly used for high-performance garments such as sports jerseys, linings and pants. Warp knits are produced with a locking stitch, which increases the fabric’s abrasion and tear resistance. If a warp knit tears, the fabric will lock, unlike a woven, which will rip. In soft signage, warp knits are the superior fabric choice because they offer dimensional stability, are easier to install into SEG frames, and do not fray. Some examples of warp knit constructions are mesh, satin and flag. Warp knits for apparel are typically printed with dye sublimation or direct digital pigment printers, while warp knits for soft signage can be printed by almost every print platform, if the fabric is properly optimized for the ink set.

Weaving

Woven fabrics are made on a loom by interlacing two sets of yarns — the warp and the fill — at right angles to each other. Woven fabrics are used in the apparel, home furnishings and soft signage markets. It’s important to note that using woven fabric for soft signage applications creates an additional set of challenges, including fraying and diagonal twill lines that can cause the graphic to look pixelated or blurry.

In the apparel market, most bottom-weight garments (e.g., pants) are woven, as are many shirt and outerwear garments. Most home furnishing fabrics are woven, with very little exception. Some construction examples of woven fabrics include, but are not limited to:

• Square (sheeting, poplin, canvas)

• Twill (left-hand twill (LHT) and right-hand twill (RHT), which have many different constructions: 3x1, 2x1, etc.)

• Herringbone

• Ripstop

• Dobby

• Sateen

• Jacquard

Woven fabrics are compatible with all print platforms if the fabric is properly optimized for the ink set.

Understanding construction puts you one step closer to ensuring you have the right fabric for your project. Read more about what you should know when discussing options with a supplier.